Optimized to Fil: Why Optimization is Important for 3D Printing

- Nov 8, 2022

- 4 min read

Updated: Nov 19, 2022

Kaitlyn Ngo. November 8, 2022

The world is constantly changing and evolving around us everyday. It is crazy to think a few years ago 3D printing was a new technological advancement that was only restricted to printing inanimate plastic objects like small structures or objects. Nowadays the 3D printing process has been incorporated into various industries in order to improve their overall workflow processes, with the constant and proper optimization of this piece of technology any company's workflow can become more effective and efficient. There are numerous ways to optimize 3D printing processes however, it depends on what the purpose is and why 3D printing is being used.

Economize Consumables

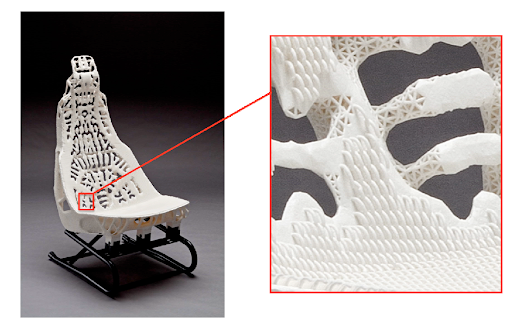

For some companies 3D printing is used as a way to save costs as it is an independent machine that does not need much handling however, with 3D printing comes expensive costs mainly due to the consumables used. This is where optimizing this piece of technology is important, there are various ways to get the most out of the consumables being used. For instance, having the proper storage space “for resin tanks and cartridges, I want to ensure they are stored in a dark place when possible.” (Leigh, 2022). This can be specifically important for companies using expensive filament, they will want to reduce costs wherever possible. When designing clothes with 3D printing the choice of filament is important as people will be wearing these pieces and they need to be wearable, durable, and comfortable. Thermoplastic polyurethane (TPU) and Thermoplastic elastomer material (TPE) are two different filaments that can be used in printing clothes. TPU is a material that “offers flexibility and elasticity” (Filament2print, 2022) and TPE is a material that has “high levels of elasticity” (Filament2print, 2022). As the fashion industry slowly starts to launch 3D pieces it is imperative the designer economize the consumables as there will be a lot of trial and error in their designing process as well as the assembly process resulting in a required great amount of filament.

Hardware

One of the most important parts of these 3D printers is their hardware. There are limitations that standard printers have and in order to improve any aspects of the end result the initial change should be in the hardware. There are devices such as “temperature sensors, humidity sensors, and X-ray cameras to monitor quality and catch errors layer by layer during the printing process.” (D'Aveni & Venkatesh, 2020). Every company has its specific uses for these printers therefore, the manufacturers of the printers need to make a product that can be used by everyone. With certain upgrades like different sensors or cameras this will optimize the workflow for different companies depending upon what the end result requires. By adding quality control to the 3D printing process, it could improve the workflow for mass production. In the fashion industry every detail is important especially when it comes to the assembly process, this is because one mistake in the numbers or any misprint can change the overall look that was originally designed. This can set the designers back as they will need to reprint either one specific part or the whole piece depending on how bad the misprint is making it inaccessible to sell to the masses.

Software and Data

Everyday there is a new technological software application put out or more data collected. Like any other piece of technology there can be many new updates or softwares that are created regularly to keep up with current technological trends. With 3D printing since it is so new there is always new softwares being created and data being recorded to optimize the workflow process of these printers. An Israeli software company has designed a new software, Printsyst, that “looks for factors that can help achieve higher consistency, yield rates, cost savings, and any dimensions of quality customers might prioritize. It suggests printing technologies, material choices, machine parameters, and even design modifications to achieve the goals selected for optimization.” (D'Aveni & Venkatesh, 2020). This kind of software can be a game changer for numerous companies. In the fashion industry, mass production is essential for clothing brands, with new software updates like this Printsyst companies are able to easily adjust and modify their pieces being printed without causing a mass disruption to the workflow process.

In this fast paced society 3D printing just like any other new trend or advancement, it is important to optimize because it opens the doors to more opportunities and this is how the world progresses. From reducing costs to increasing efficiency, these 3D printing machines are one of numerous new up and coming evolutionary inventions that can optimize any workflow even in the fashion industry.

References

D'Aveni, R. A., & Venkatesh, A. (2020, September 25). How to make 3D Printing better.

Harvard Business Review. Retrieved November 5, 2022, from https://hbr.org/2020/09/how-to-make-3d-printing-better

Leigh, R. (2022, September 17). How to create an effective 3D printing workflow. Robotic

24/7. Retrieved November 5, 2022, from https://www.robotics247.com/article/how_create_effective_3d_printing_workflow

What role do flexible filaments play in the fashion industry. Filament2Print. (2022,

February 18). Retrieved November 5, 2022, from https://filament2print.com/gb/blog/132_flexible-filaments-in-the-fashion-industry.html#:~:text=Wide%20variety%20of%20materials&text=Flexible%20FDM%203D%20printing%20filaments,flexibility%20and%20a%20certain%20elasticity.

Comments